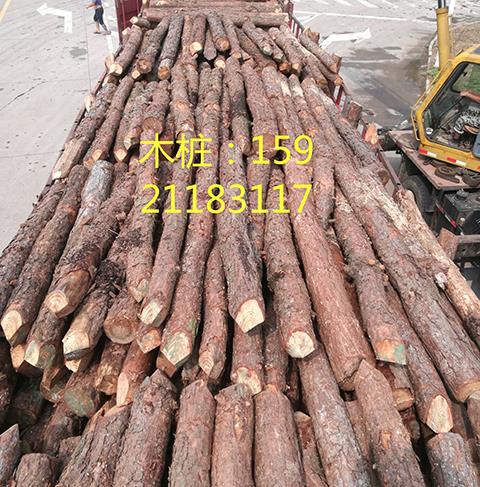

Pitch pine wood pile

Pitch pine wood pileCommonly used pile driving machines include hand winches and diesel pile drivers.hydraulic excavatorIt is also often used for driving wooden piles.hydraulic excavatorWhen driving piles, two people are required to hold the piles in place, turn the bucket upside down to hold down the wooden piles, and press the wooden piles into the foundation to a certain depth to stabilize themselves. Then let the pile helpers go away and the excavator will press down the pine piles. Generally, each time3-5minJust one pile can be driven, which is more efficient.

In order to achieve good squeezing effect, increaseBearing capacity of foundation, when driving piles, they must be driven from the 4th perimeter of the base to the inner circle. The piles are preferably arranged in a plum blossom shape, and the distance between piles should not be less than3times the pile diameter.

After piling is completed, the pile heads should be sawn flat according to the designed elevation so that the top of each pile is basically kept at the same level. The silt squeezed out during piling should be excavated and laid on top of the piles.20-750pxthickGraded sand and gravelThe mattress is laid and compacted, and then the bottom slab concrete is poured to ensure that the foundation transmits part of the load to the soil between the piles through the mattress and adjusts the sharing effect between the piles and the soil.

Placing a mattress layer under the foundation can reduce thepile-soil stress ratio, giving full play to the role of the soil between piles, you can increase the value and reduce the stress on the bottom surface of the foundation.stress concentration.By changing the thickness of the mattress, adjust the sharing of the vertical load of the piles. The thinner the mattress, the higher the percentage of the load the piles bear in the total load, and vice versa. If there is no mattress, the soil between the piles cannot be used. effect.